Leaders in Aggregate Mining & Processing: WM. Mueller & Sons - Your One-Stop Solution for Asphalt Paving, Excavating & Grading, and Aggregate & Asphalt Delivery!

Aggregate and Asphalt Products

Markets Served

Connecting our Community for Over a Century

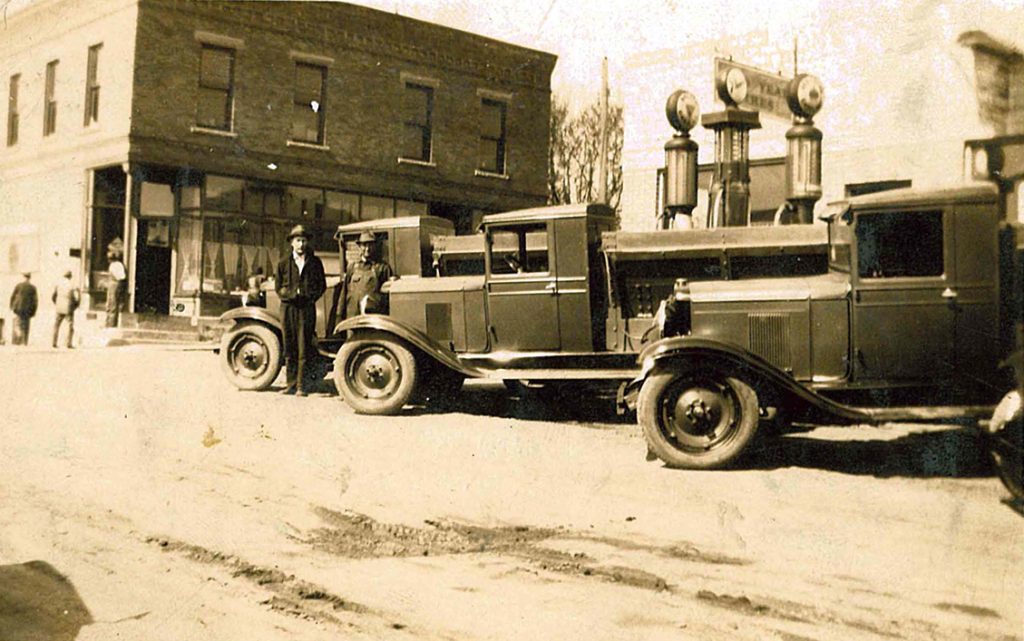

In 1908, William Mueller purchased a dray and livery business in Hamburg, Minnesota. Street repairs were often the job of the drayman, who shoveled gravel by hand into a special type of dump wagon. By removing the floorboards, the gravel could be spread along the streets or roads.

In 1911, the first car appeared in Hamburg and within a short time, more and more cars arrived. In the early spring, when dirt roads began to rut up from the weight of the “new-fangled machines,” the cry of “Get a horse” could be heard. Traffic increased every year, and the need for repairs to the roads also increased. More gravel was needed to surface the streets and roads, and Mueller soon purchased a huge hand scraper and improvised a ramp. A pulley and gas engine alleviated the hand shoveling of the gravel into wagon boxes.

William Mueller began with horse-drawn dump wagons, shovels, one-hand scoops and hired manual labor.

Expansion 1919

In 1919, when demand for road construction grew, Mr. Mueller sold the dray business and purchased two Model T Ford trucks to speed up deliveries. This was the “birth” of Wm. Mueller, Road Construction.

The increased number of automobiles demanded better roads, so each year, additional machinery and equipment for loading, screening, and scraping were purchased. In 1927, William purchased four Chevrolet gravel trucks from the local dealership.

As William’s children grew and married, they and their spouses also became involved. Sleeping and cooking shacks on wheels were purchased, and a nomadic life began during the summer months. Each family had a separate trailer. The entire family, with their trailers, left in the spring of the year to build roads throughout the state. Kerosene lamps were used in trailers. Later they were able to hook up electricity.

In 1937, Mr. Mueller took his son and sons-in-law into the business as partners; the company has since been known as Wm. Mueller & Sons.

In 1941, the company purchased gravel deposits at Carver, Minnesota. William’s son, Ralph, started operations at the newly acquired Carver Pit. There was no electricity and all conveyors and machines operated with individual engines.

Under the perseverance of the family, the business of Wm. Mueller & Sons continued to thrive, and in 1955, the third generation of family members began to join into the family enterprise.

In the ‘60s a bituminous plant was built at the Carver Pit and blacktop paving was added.

In May 1975, Jefferies Pit, adjacent to Carver Pit, was purchased, as well as other sand and gravel deposits in various areas, thus providing washed sand, plaster and concrete sand, rocks, and boulders to a vast area. Other services rendered by the company included ground construction, paving, land clearing, drag lining, snow plowing and other more basic types of jobs.

On June 30, 1985, the new Rohr Gravel Mining Dredge Machine was dedicated. It was the first gravel-mining dredge in the United States with the capability to use its 6½ cubic-yard bucket to extract raw aggregates from the waters of Carver Pit.

In response to the increasing demand, a larger dredge with a 16-cubic-yard bucket was installed in the late 1990s. With the larger bucket, this dredge has a higher production rate, with the ability to dig deeper, faster, and haul larger quantities of gravel at Carver Pit.

Family members of the fourth and fifth generations have taken over operations. The company continues growing, adding a new asphalt plant and additional pit locations.

Aggregate and Asphalt Pick Up for Contractors Available at Multiple Wm. Mueller & Sons Facilities

Get In Touch!

contact us

join our team